Good housekeeping is more than just cleanliness—it’s a critical part of workplace safety and efficiency. When combined with the Kaizen 5S technique, it creates a structured, sustainable system for organizing any environment—especially in factories, construction sites, offices, and industrial facilities.

In this blog, we’ll explore what housekeeping means, break down the 5S technique, and show how these two practices work together to reduce hazards, boost productivity, and foster a culture of continuous improvement.

🧼 What is Housekeeping in the Workplace?

Housekeeping refers to maintaining order, cleanliness, and safety in a work environment. It’s a proactive system to reduce clutter, organize tools and materials, and ensure walkways and work areas are free of hazards.

Poor housekeeping leads to:

- Increased risk of slips, trips, and falls

- Fire hazards due to blocked exits or flammable clutter

- Lower efficiency and morale

- Poor inspections and audits

Good housekeeping is a foundation of health, safety, and operational excellence.

⚙️ What is the Kaizen 5S Technique?

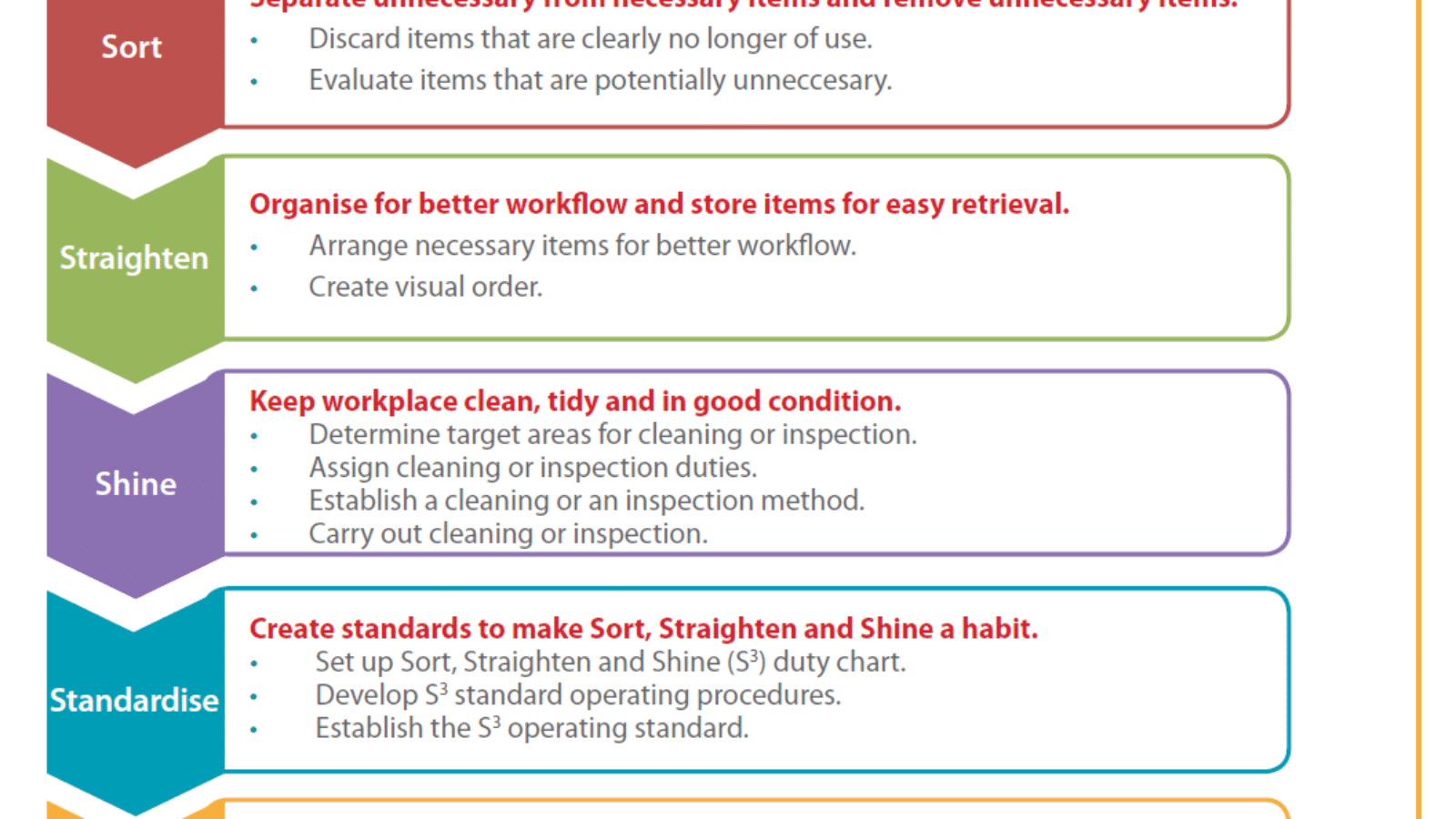

5S is a workplace organization method rooted in Kaizen—the Japanese philosophy of continuous improvement. The 5S steps are:

| Japanese Term | English Meaning | Description |

|---|---|---|

| Seiri | Sort | Remove unnecessary items from the workplace. Keep only what’s needed. |

| Seiton | Set in Order | Organize tools and materials for easy access. Label and store items in logical places. |

| Seiso | Shine | Clean the workspace thoroughly. Inspect while cleaning. |

| Seiketsu | Standardize | Establish routines, checklists, and visuals to maintain consistency. |

| Shitsuke | Sustain | Build discipline. Promote habits that keep the 5S system going long-term. |

🧲 How Housekeeping and 5S Work Together

Both systems aim to:

- Improve safety

- Boost efficiency

- Reduce waste

- Increase employee engagement

Here’s how they integrate:

| Housekeeping Activity | 5S Equivalent |

|---|---|

| Removing unused items | Seiri (Sort) |

| Organizing tools by type/use | Seiton (Set in Order) |

| Daily cleaning and inspection | Seiso (Shine) |

| Visual instructions, color codes | Seiketsu (Standardize) |

| Regular training, audits | Shitsuke (Sustain) |

🏭 Benefits of Implementing 5S + Housekeeping

✅ Improved Safety – Reduces risk of injuries by removing hazards

✅ Time Savings – Workers can find tools and materials faster

✅ Cost Savings – Prevents tool loss, overstocking, and production delays

✅ Higher Morale – Clean, organized environments reduce stress and increase pride

✅ Better Compliance – Supports ISO 45001, OSHA, and other HSE audits

🛠 How to Start 5S in Your Workplace

- Do a walkthrough to identify problem areas.

- Form a 5S team with representatives from all departments.

- Start with one zone or area (pilot).

- Use checklists, red tags, labels, and storage boards.

- Train staff in each of the 5S principles.

- Audit regularly and reward good practices.

📸 Visual Tools You Can Use

- Red Tag System: For identifying unnecessary items

- Shadow Boards: To organize and visualize tool placement

- Floor Markings: For walkways, equipment zones, and safety

- 5S Audit Sheets: To review compliance regularly

📢 Final Thoughts

Good housekeeping combined with the Kaizen 5S technique is not just a cleanliness campaign—it’s a productivity and safety revolution. Implementing these practices means fewer accidents, higher output, and a workforce that takes pride in its workplace.

Start small. Be consistent. And remember: a clean place is a safe place!

Add a Comment