Cranes are vital workhorses on construction sites, ports, and industrial plants. But with great lifting power comes great responsibility — ensuring crane safety through rigorous inspections isn’t just good practice, it’s a legal and ethical necessity. This blog outlines a comprehensive Crane Inspection Safety Checklist to help operators, safety officers, and project managers maintain safe and compliant lifting operations.

Why Crane Inspections Matter

Crane-related accidents can lead to catastrophic injuries, fatalities, and extensive property damage. Most of these incidents are preventable. Regular crane inspections reduce the risk of:

- Structural failures

- Load drops

- Electrocutions

- Overturning

- Mechanical breakdowns

Regulations from OSHA (Occupational Safety and Health Administration), ANSI, and country-specific safety codes (e.g., PEC in Pakistan) require periodic inspections, operator training, and thorough documentation.

Types of Crane Inspections

Understanding the timing and depth of inspections is critical:

- Pre-Operational Inspections (Daily or before each shift)

- Frequent Inspections (Monthly or based on usage)

- Periodic Inspections (Quarterly to annually)

- Post-Repair or Post-Assembly Inspections

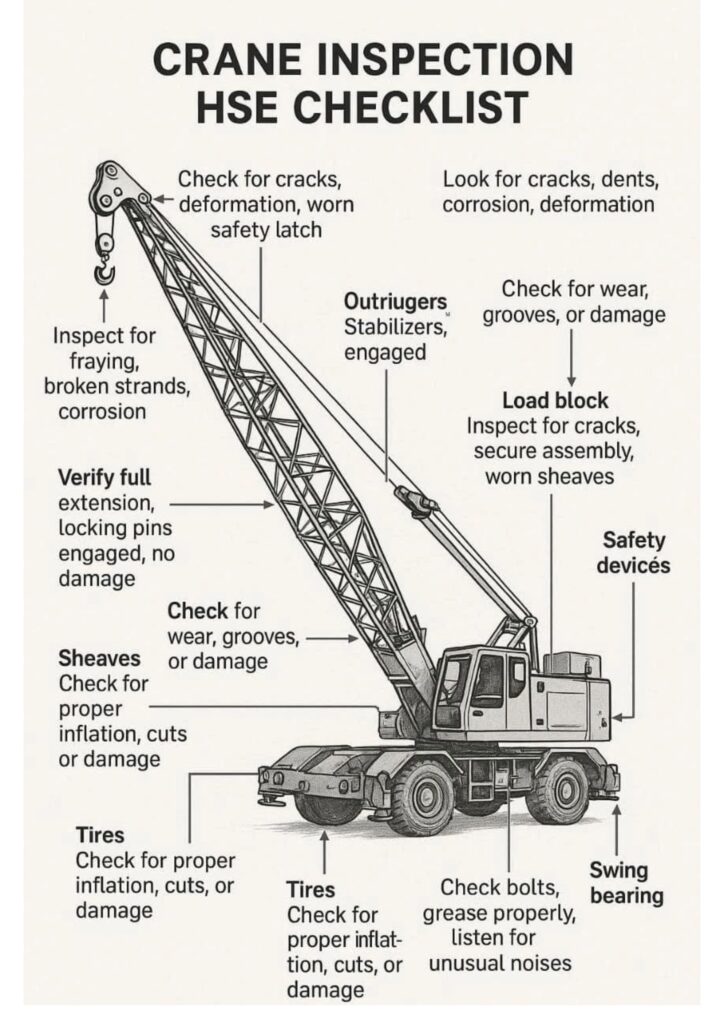

✅ Crane Inspection Safety Checklist

Here’s a structured checklist to guide crane safety inspections. This list is adaptable for tower cranes, mobile cranes, overhead cranes, and crawler cranes.

1. General Condition

- Crane body free of visible cracks, corrosion, or deformities

- Operator cabin clean and unobstructed

- Safety decals and warning signs legible

2. Mechanical Systems

- Hydraulic systems leak-free and fluid levels adequate

- Brakes functioning properly (main, swing, and travel)

- Hoist ropes free of kinks, wear, or bird-caging

- Drums, sheaves, and bearings well-lubricated

3. Electrical Systems

- Wiring intact, properly insulated, and secured

- Control panels functioning with no overheating

- Emergency stop button operational

- Limit switches properly adjusted

4. Load Handling Devices

- Hook free from cracks, deformations, and excessive wear

- Safety latches functional and secure

- Load charts available and visible to the operator

- Outriggers or counterweights properly deployed and locked

5. Safety Equipment

- Fire extinguisher present and accessible

- Audible alarms (horns, backup alarms) functional

- Anti-two block system and load moment indicators tested

- Wind speed indicator working (for tower cranes)

6. Ground and Site Conditions

- Crane setup on firm, level ground

- No overhead obstructions (wires, structures)

- Safe distance from power lines maintained

- Barricades and signage in place around crane area

7. Documentation and Training

- Inspection log up to date

- Operator certification valid and displayed

- Maintenance records available

- Incident reports (if any) reviewed and corrective actions taken

Best Practices

- Use a digital checklist app to streamline and record inspections.

- Train operators and maintenance crews regularly on updated standards.

- Schedule inspections during low-activity periods to minimize downtime.

- Involve third-party certified inspectors for periodic assessments.

Conclusion

Crane inspections are not a box-ticking exercise—they’re a frontline defense against disaster. A proactive safety culture, supported by detailed checklists and trained personnel, can prevent injuries, protect investments, and maintain compliance. Always remember: inspect to protect.